-

Polyacrylamide is simply called PAM, a water- soluble high polymer and widely used in petroleum, paper-making, metallurgical,textile, chemical and environment protection fields. There are three categories of anionic, cationic and non-ionic type.It is widely used in many fileds like Water Treatment, Oil Exploration, Sludge Dewatering, Paper Making, Textile, Sugar Making, Coal washing and Incense Making, etc.PAM can also be used in many other fields like Coal washing, Ore-dressing, Sludge Dewatering and so on.

Polyacrylamide is simply called PAM, a water- soluble high polymer and widely used in petroleum, paper-making, metallurgical,textile, chemical and environment protection fields. There are three categories of anionic, cationic and non-ionic type.It is widely used in many fileds like Water Treatment, Oil Exploration, Sludge Dewatering, Paper Making, Textile, Sugar Making, Coal washing and Incense Making, etc.PAM can also be used in many other fields like Coal washing, Ore-dressing, Sludge Dewatering and so on. -

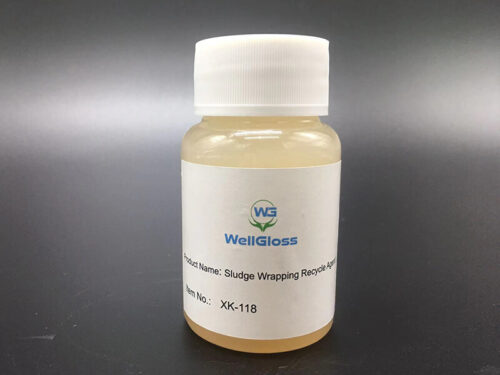

Sludge wrapping recycle agent is the latest generation of papermaking sludge recycle product developed and produced by our company. This product in the process of sludge added, its unique bridge make sludge to produce polymer cationic branched chain structure, combined with pulp rapidly, adsorption and reaction of cationic floc quickly fill in the gap between crude fiber, make it have stronger affinity, generate new reaction, enhance the sludge and slurry mix and match, make the sludge evenly into a paste, make sheet evenness got fully improve, improve paper folding burst degrees and ring crush strength, improve the filtering performance, prolong the service life of wool, improves the production efficiency, reduce the environmental pressure of sewage treatment. This product is widely used for corrugated paper, box board paper, white board paper, cattle card paper, etc.

Sludge wrapping recycle agent is the latest generation of papermaking sludge recycle product developed and produced by our company. This product in the process of sludge added, its unique bridge make sludge to produce polymer cationic branched chain structure, combined with pulp rapidly, adsorption and reaction of cationic floc quickly fill in the gap between crude fiber, make it have stronger affinity, generate new reaction, enhance the sludge and slurry mix and match, make the sludge evenly into a paste, make sheet evenness got fully improve, improve paper folding burst degrees and ring crush strength, improve the filtering performance, prolong the service life of wool, improves the production efficiency, reduce the environmental pressure of sewage treatment. This product is widely used for corrugated paper, box board paper, white board paper, cattle card paper, etc. -

Usage:

Usage:- Location of enzyme supplementation: crushed pulp tower, pulp storage tower after heat dispersion or after pulp is concentrated or before sizing. Usually it can be added at one point or several points simultaneously.

- Mode of enzyme supplementation: Based on pulping method, enzyme is supplemented by batch or added continuously.

- Recommended dosage: 60~150g/T absolute dry pulp; the optimum dosage is determined according actual trial results.